Dam construction

Contents |

[edit] Introduction

Dams are barriers, usually constructed across rivers, to hold back and contain water in a lake or reservoir. Dams are usually built using concrete, or natural materials such as earth and rock, and in cases such as the Hoover Dam and the Three Gorges, are major engineering projects with a construction programme lasting many years.

For centuries, dams have been a vital part of the water infrastructure, serving many different purposes, including:

- Water supply: Reservoirs store rainwater before it is filtered and processed for human use.

- Hydroelectric power: Reservoirs store rainwater to be used in hydroelectric power stations to generate electricity.

- Flood control: Reservoirs control water flow into rivers after heavy rain.

- Irrigation: Water can be stored in reservoirs for irrigating land during dry periods.

- Navigation: Dams can be used to raise the upstream water level to improve navigation conditions.

[edit] Types of dam

[edit] Arch dams

An arch dam is curved in an arch-shape, with the top of the arch pointing back into the water, to create a very strong structural form, resistant to the water pressure behind the dam. Arch dams are usually made from concrete and require a good rock support for foundations and the sides, so are commonly used in narrow, steep-sided valleys.

[edit] Buttress dams

Buttress dams have triangular-shaped walls, or buttresses, which are spaced at intervals on the downstream side, resisting water pressure against the upstream side. They must be constructed on sound rock and are typically made of concrete or masonry. Because of the spacing between the buttresses they can be quite efficient in terms of materials.

[edit] Embankment dams

Embankment dams have historically been quite common in the UK, usually found in sites with wide valleys. They are commonly constructed using natural materials such as compacted earth or rocks which are often locally quarried or excavated. In cross-section, an embankment dam is hill or bank shaped, with a central core made from an impermeable material such as clay soils or concrete, to prevent water passage.

[edit] Gravity dams

Gravity dams rely on gravity to hold them in place. They are generally made from concrete, masonry, or both, and in cross-section are typically triangular. They need to be built on sound rock and are suited to wide or narrow valleys.

[edit] Spillways

Spillways form part of a dam and are used to pass overflow water over, around or through a dam, in a safe and controlled way. The different types of spillway include:

- Overflow spillway: This allows water to flow over and down its front face as it is lower than other dam sections, and is curved to control the flow of water. Most commonly constructed as part of gravity or buttress dams.

- Side channel spillway: This is located a short distance upstream of a dam, and diverts water into a side channel then into the river downstream of the dam. They are mainly used with embankment dams.

- Shaft spillway: This is a circular hollow tower that sits in the reservoir near the dam. When the water level rises, it flows into a funnel at the top of the shaft which diverts the water downstream.

[edit] Dam construction

Dam construction is often complex and requires a wide range of professionals from different disciplines.

- Civil engineers are generally responsible for determining the best type of dam for the site, and for producing technical drawings showing the construction process.

- They will consult with engineering geologists and hydrologists on the technical details of the site and the required specifications dependent on the amount of water involved.

- Mechanical engineers will be contracted to design the necessary pipework, valves and floodgates.

- Geotechnical engineers will determine whether the rock or soil below the proposed dam is strong enough to accommodate the weight and for determining possible permeability.

In very broad terms, the typical sequence of events for dam construction is as follows:

[edit] River diversion

Water flowing in a river or stream is diverted to create a dry area in which to construct the dam.

Lower flows will be capable of diverting through tunnels or channels built around the side of the dam area, excavated using explosives where necessary.

Higher flows may be too difficult to divert using separate channels, so instead a dry pit is formed on one side of the river, leaving the other side open for water to flow through. The dam is constructed in sections, with dry areas built in sequence. Openings are provided in the dam to allow the river to flow through.

[edit] Foundations

The foundation is built below the original ground level, with weaker soils or rock removed and replaced with stronger materials if necessary. Cracks and fissures in the rock foundations must be filled with grout to stop water leakage. Holes are drilled into the rock and grout pumped into them, spreading outwards and filling the cracks.

[edit] Building the dam

Concrete dams will need a large quantity of ready concrete, so a concrete batching plant is often built on site. Concrete is then transferred to the dam either using a system of conveyor belts or using trucks and cranes.

The traditional method of placing the concrete is to pour it into a formwork mould made in the required shape of the dam. The dam is built upwards 1-2 m at a time, and the concrete left to cure before the next section is formed on top.

An alternative method is to spread a concrete mix and compact it down using rollers. The dam is raised in steps of around 600 mm at a time. Low concrete walls on the upstream and downstream faces are formed first, with concrete then spread in thin layers in between the walls, before being compacted using rollers.

Embankment dams are constructed in a series of thin layers from the bottom upwards. Bulldozers spread fill material in a thin layer, usually 300 mm thick if using earth, or up to 1 m thick for rock-fill. The core of the dam is also constructed in layers so that it maintains the same height as the rest of the dam. A protective layer is formed on the upstream face once the full height has been achieved. This protects against wave damage and often provides waterproofing.

[edit] Post-construction

Once the dam has been constructed the reservoir can then be filled, if it has not been during construction (in the case of high flow rivers). Valves and floodgates must be extensively tested, and the behaviour of the dam must be monitored.

[edit] Safety

The Reservoirs Act (1975) is the updated version of the Reservoirs (Safety Provisions) Act (1930), which introduced safety laws for UK reservoirs holding 25,000 cubic metres of water or more.

The act provides for a panel of civil engineers who are responsible for checking the safety of reservoirs and their dams. Reservoir owners are legally responsible for maintaining safety and for employing civil engineers to regularly monitor them between the panel’s inspections.

Embankment dams can show cracks and bulges on their downstream and upstream faces, which can indicate instability. The appearance of hollows can indicate that the dam has been being overtopped by floodwater with it proceeding to erode the downstream slope.

The dam can also be inspected for signs of water leakage underneath which can gradually create an unstable cavity. Concrete dams are built with inspection galleries running through them in the form of a tunnel. These are used by engineers to inspect the condition of the dam from the inside as well as the outside. They examine for any signs of potential problems with the foundation, water leakage, or movement.

[edit] Related articles on Designing Buildings

- Barrage.

- Caisson.

- Check dam.

- Coastal defences.

- Dredging.

- Dual purpose reservoirs.

- Flood defences.

- Hydropower.

- Irrigation.

- Land reclamation.

- Relief well.

- River engineering.

- Spelga dam.

- Tidal lagoon power.

- Thames barrier.

- Trading systems for water resources.

- Water engineering.

- Water transfers and interconnections.

Featured articles and news

Increased vigilance on VAT Domestic Reverse Charge

HMRC bearing down with increasing force on construction consultant says.

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

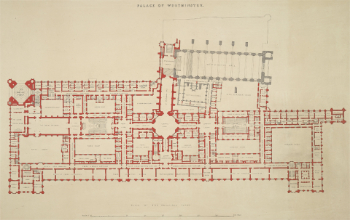

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

Comments

[edit] To make a comment about this article, click 'Add a comment' above. Separate your comments from any existing comments by inserting a horizontal line.